AlignKAT™

AlignKAT™ is designed with advanced software and hardware enhancements, providing a solution for all orienter issues and wafer substrates. Improve hand-off accuracy to reduce wafer breakages/system downtime, and increase throughput and wafer substrate orientation capability with AlignKAT™.

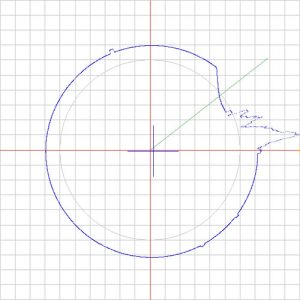

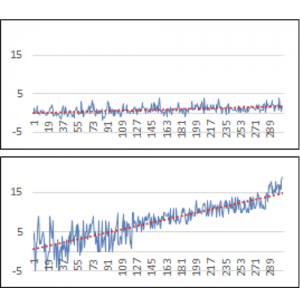

ABLE TO FILTER OUT NOISE AND AMBIGUOUS SIGNALS

ANY TYPE OF WAFERS CAN BE ORIENTED WITH ERRORS

DATA ACQUISITION FEATURE ALLOWS FOR DETECTION OF ROBOT OR LOADLOCK MIS-CALIBRATION

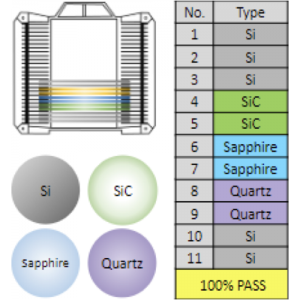

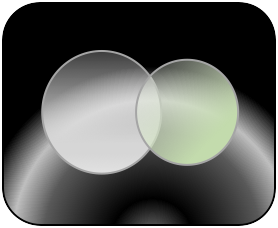

Detection of Non-standard Wafers

AlignKAT™ has the capability to detect non-standard wafers such as transparent, semi transparent, double flat and triple flat wafers.

Field Proven

Extensive field data at over 25 customer sites with more than 5 years of performance results. AlignKAT™ shows exceptional reliability at all type of situations.

Wafer Data Logging

Up to 500,000 wafer data logs can be stored and used to figure out the root cause of issues such as wafer handoff, sliding on pedestal, motor vibration, or wafer edge status.

Robust Algorithm

Prevent the misalignment using a geometrical analysis and learning algorithm removing signal noise from external influences.